Optimize Your Power Plant Operations with Leakwise Oil on Water Monitoring

Customizable and Easy-to-Use Monitoring Systems for Enhanced Efficiency and Safety

Leakwise Oil on Water Monitoring System for Power Plant Industries. Our advanced monitoring system is designed to enhance the efficiency and safety of power plant operations by providing reliable and continuous detection of oil on the surface of water.

Power Generation Plants

Enhance Your Power Plant Operations with Leakwise Oil on Water Monitoring

Our advanced monitoring system is designed to enhance the efficiency and safety of power plant operations by providing reliable and continuous detection of oil on the surface of the water.

Environmental authorities allow only a few PPMs of oil in the discharge from separators. Online ppm monitors are usually costly and require routine cleaning, compensation, filtering and zeroing.

The Leakwise ID-223 Oil Sheen Detector can be used as an alternative (or as a backup) online monitor, which will set off an alarm in case of oil sheen detection, indicating that there is an upset in the water treatment process and the amount of discharged oil exceeds the permitted level.

Fuel fired power generation plants have several Leakwise ID-223 Oil Sheen Detectors installed in oil and stormwater collecting sumps and separators/interceptors located in containment areas near tanks. These sumps need to be monitored for safety and environmental purposes. Leakwise sensors can also control the sumps’ outlet valve to prevent oil from being discharged into stormwater drains or rivers.

Only oily water will be diverted to treatment, thus reducing the plant’s treatment costs. For more information, refer to Leakwise Application Notes “Above-Ground Oil Storage Tanks” and “Oil Storage Tank with a Floating Roof”.

Open Cooling Water Systems

A Leakwise ID-223 Oil Sheen Detector can detect leaks from heat exchangers along the cooling water open channels, at cooling water intake or at discharge points.

Closed Cooling Water Systems

Suppose cooling water monitoring is required in a closed system. The Leakwise ID-223 Oil Sheen Detector should be installed in a sampling-settling tank mounted along a cooled bypass from the primary cooling water pipeline.

Oil Sheen Detection in Condensate Water

A Leakwise ID-223 Oil Sheen Detector installed in a condensate tank with atmospheric pressure can detect an oil sheen in high-temperature condensate water.

Hydroelectric power generation plants are usually located in clean nature sites with very high environmental protection standards. Large volumes of water are used for generating power as well as for cooling purposes. For more information, refer to Leakwise Application Note “Hydro-Electric Power Plants”.

Hydrocarbon Pipeline

Protecting the Environment and Ensuring Pipeline Integrity

Hydrocarbon pipelines play a critical role in oil and gas transportation, but they can also pose significant environmental risks if not adequately monitored and managed.

Pipeline companies install oil collection containments in sensitive locations along the pipeline (e.g. near rivers and groundwater drinking wells) for monitoring oil leakage. When an ID-223 Oil Sheen Detector installed in such a containment detects oil or oil on water, it sets off an alarm in a remote location.

The ID-223 Detector may be installed in unmanned remote locations where power and communication lines are seldom available. In such cases, the system can be powered by solar panels, and communication can be done wirelessly.

Most pipeline pumping stations have either oil-water separators or retention tanks for collecting oil spills and stormwater run-offs that may carry oil. Water is continuously discharged from the separator or retention tank directly into the local public drainage system.

An ID-223 Oil Sheen Detector is installed near the separator outlet or in the sump to monitor the water discharge continuously. If an oil sheen is detected, an alarm is triggered, the water outlet valve is automatically closed, or the Leakwise system can turn the water pump off. An ID-225 Oil Layer Thickness Monitor can be installed in the separator to monitor the thickness of the accumulated oil layer.

Many shut-off valves are built along the pipeline for emergency and maintenance. In some areas, due to specific environmental regulations, new shut-off valves must be installed in concrete containment where leaks accumulate and can be detected.

Leakwise Oil on water monitoring system ID-223 Oil Sheen Detectors installed in these containments continuously monitor these unmanned shut-off stations and send an alarm to a remote location in case of oil detection.

Hydro-Electric Power Plants

Protecting the Environment and Optimizing Operations

Hydro-electric power plants rely on the efficient management of oil and other hydrocarbons to generate electricity. However, these substances can pose a significant environmental risk if not properly monitored and managed

In most plants, pumps installed at the bottom of the sump discharge the water directly to the river. For immediate notification and to prevent oil from being pumped out to the river, sumps/turbine pits should be continuously monitored for oil sheens.

Cooling oil and rainwater is collected under the power plant’s transformers into an underground tank. A Leakwise lD-223 installed in this tank detects leaks of transformer oil and can be used for preventing the discharge of oily water into a river or public drainage system.

This can be an additional way to monitor transformer performance before it fails due to oil leaks.

Power Distribution

Enhancing Safety and Efficiency

Oil-filled power distribution transformers are critical components of power distribution systems, but they can also pose significant environmental risks if not adequately monitored and maintained.

Utilities have hundreds of transformer substations. In each substation, there are usually several transformers. Each transformer contains a high volume of cooling oil.

A catch basin is built under the transformer to contain small leaks or all the transformer oil in case of a significant breakdown. Most substations are unmanned, and continuous remote monitoring of oil leaks is essential for meeting operational, safety and environmental requirements.

Small oil leaks or spills drain into the catch basin. This oil can be carried away with the rain into the public storm drain system when the catch basins are overfilled with water. To prevent this, water is collected from the catch basins into a central sump of the substation. From there it is discharged by gravity or by a pump into a public storm drain system or to a nearby river.

A Leakwise ID-223 Oil Sheen Detector is installed in the sump or even directly inside the catch basin. When an oil sheen is detected on the water or at the bottom of the sump (if it is dry), an alarm in the remote is set off, and the water discharge pump or discharge valve will be shut off automatically.

Following the oil alarm, maintenance personnel will come to remove the oil. Alternatively, they may choose to pump the oily water into an oil retention tank. A Leakwise ID-225 Oil Thickness Monitor can be installed to monitor the oil layer thickness up to 200 mm in this retention tank.

After a short retention time, water can be drained from the bottom of the tank, and additional oily water can be added to it until the oil layer is thick enough to be removed (e.g., by a vacuum skimming truck). This process can prevent the removal of a large volume of water by stopping skimming until enough oil has accumulated at the upper layer of the tank.

In large cities, high voltage power cables are run underground. These cables are insulated with large quantities of oil, which is constantly pumped along the cable through underground pumps. Transformers are installed in building cellars and in underground vaults. Access to these cables and supporting equipment is through maintenance holes.

The underground cable service maintenance holes can fill up with water and utility maintenance teams must pump the water out into the drainage system. If oil is detected, the water must be removed for treatment. Oil detection can be done either in a fixed installation of Leakwise ID-221 or ID-223 Detectors or by using a transportable ID-223 Oil Sheen Detector, 12/24 VDC can operate that from the service trucks.

Product Solution

Leakwise Oil On Water monitoring system with a highly reliable and scalable solution for detecting and monitoring oil spills. The system could be customized to meet the needs of any application, and would provide personnel with real-time data and alerts to ensure quick and effective response to oil spills.

ID-225 Sensor

Floating sensor for monitoring thickness of hydrocarbons & organic solvents in wet sumps.

OPERATING RANGE :

- Oil Monitoring Range: ID-225/100: 1 – 100 mm (0.04 – 4.0 in); ID-225/200: 1 – 200 mm (0.04 – 8.0 in)

- Water Level Variation: Minimum: 30 cm (~12 in) above well/tank/sump bottom.

- Maximum: 45 m (~150 ft.).

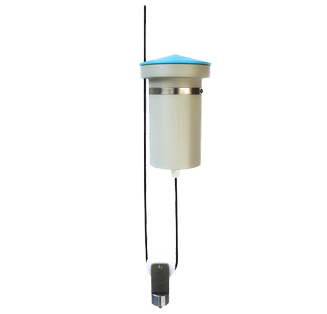

ID-223 Sensor

Floating sensor capable of monitoring hydrocarbons and other organic solvents on water and in sumps that may be dry.

OPERATING RANGE :

- Detection Range: 0.3 – 20 mm (0.01 – 0.8 in) of hydrocarbon on water or brine

- Water Level Variation: Depends on sensor sub-model – see below

ID-221 Sensor

Floating sensor capable of monitoring hydrocarbons and other organic solvents in wet sumps.

OPERATING RANGE :

- Detection Range: 0.3 – 25 mm (0.01 – 1.0 in) of hydrocarbon on water or brine

- Water Level Variation: Minimum: 30 cm (~12 in) above well/tank/sump bottom;

- Maximum: 45 m (~150 ft.).

See the Future of Oil Spill Detection:

Live Demo of Leakwise Technology

Oil spills can cause significant environmental damage and costly cleanup efforts. That's why it's important to have an early warning system in place to detect oil on water before it's too late. With the Leakwise oil on water detection system, you can do just that.

The benefits of the Leakwise technology are numerous. It can provide an early warning system for oil spills, prevent costly cleanup efforts, and help protect the environment. It's a must-have tool for any industry that deals with oil or other hazardous liquids.

If you're interested in learning more about the Leakwise technology and how it can benefit your industry, please fill up the form our team will get back to you shortly to answer any questions you may have and provide additional information.